Authored by Pete Keener, RRC, RRO, CIT - Department Manager, Building Science Solutions, Intertek, and originally published in the Chamberlin Roofing and Waterproofing Summer 2021 Quarterly Newsletter.

Authored by Pete Keener, RRC, RRO, CIT - Department Manager, Building Science Solutions, Intertek, and originally published in the Chamberlin Roofing and Waterproofing Summer 2021 Quarterly Newsletter.

This question has been asked for years in the roofing industry when discussing Electronic Leak Detection (ELD). This article will attempt to explain the differences between the two technologies, the pros and cons of each and the limitations of both. In the “good old days”, architects and roof consultants could simply require a flood test of the asphalt or coal tar pitch built-up roof (BUR) system. Unless the system was a complete failure, the multiple layers of protection in a BUR would keep the water on top the roof system until the drain plugs were removed and the design team could be sure there are no breaches in the roofing system. Today with EPDM (ethylene propylene diene terpolymer), PVC (polyvinyl chloride) and TPO (thermoplastic polyolefin), all single-ply membranes, flooding the roof system may become more problematic. Punctures in the membrane, open seams and cold welds open the roof system up to failure if the roof system is flooded with water and the above-mentioned breaches are present. Small breaches can go undetected until damaging water leaks into the building. Flood testing the entire roof is time consuming, labor intensive and may introduce excessive loads on the building structure.

For over two decades, the waterproofing industry has used electrical current to precisely locate membrane openings or “breaches”. Very simply, an electrical charge, either high voltage or low voltage, is created which detects differences between a non-conductive roof membrane and a grounded conductive structural substrate. Here is where the similarities and differences in high voltage and low voltage start. High voltage and low voltage testing methods have the same requirements:

- A conductive substrate directly below the membrane (or a conductive path of water from the membrane to the grounded deck).

- An exposed membrane (no overburden like plants, soils, gravel or other medium on top of the roof surface).

- There must be a good ground connection to the metal or concrete deck.

- There must be a good electrical path to ground. (The ground is established by wet insulation down to the roof deck and/or a conductive substrate directly under the roof membrane.)

Low Voltage ELD

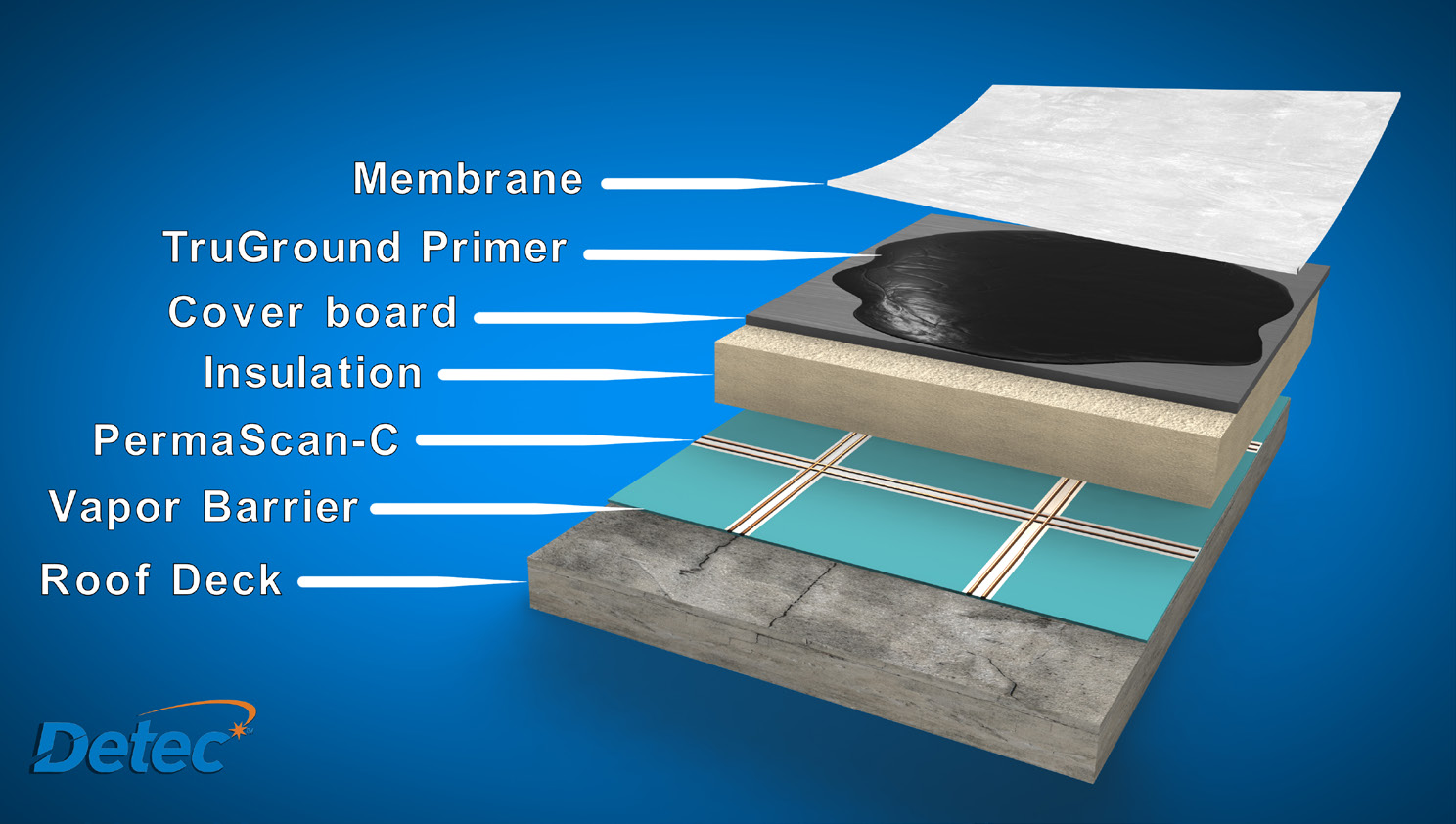

Low voltage ELD requires a wet roof surface to “activate” the conductivity of the system. The technician either places a “trace wire” around the area to be tested or uses an ELD system that has “built-in trace wire”. The wet roof surface becomes the upper conductive surface, and the conductive roof deck becomes the bottom conductive surface. If you have a wood deck with no conductive primer under the roof membrane, the system will not be “conductive” and you will not be able to test the system. The roof membrane and roof insulation become the insulator between the upper and lower conductive surfaces. If you have a breach in the roof membrane the current between the upper conductive surface and the lower conductive surface creates an electronic short between the two surfaces. It is at this point, ELD becomes confusing and controversial.

Low voltage ELD requires a wet roof surface to “activate” the conductivity of the system. The technician either places a “trace wire” around the area to be tested or uses an ELD system that has “built-in trace wire”. The wet roof surface becomes the upper conductive surface, and the conductive roof deck becomes the bottom conductive surface. If you have a wood deck with no conductive primer under the roof membrane, the system will not be “conductive” and you will not be able to test the system. The roof membrane and roof insulation become the insulator between the upper and lower conductive surfaces. If you have a breach in the roof membrane the current between the upper conductive surface and the lower conductive surface creates an electronic short between the two surfaces. It is at this point, ELD becomes confusing and controversial.

In July of 2019, ASTM published the first industry-wide standard on electronic leak detection for roofs (ASTM D-8231-19 Standard Practice for the Use of a Low Voltage Electronic Scanning System for Detecting and Locating Breaches in Roofing and Waterproofing Membranes). This new ASTM standard does not cover high voltage which we will discuss later in this article. ASTM D-8231 provides clear direction and a clearer understanding of low voltage testing. The new standard tries to clarify some of the misunderstanding and misconceptions not addressed in the first ASTM standard (ASTM D7877). This new standard also describes how moderately conductive membranes like black EPDM and cold-applied liquid membrane roofing can now be electronically tested. The new ASTM standard mandates that testing must be performed before overburden (soil, pavers) is installed. This is significant when dealing with plaza decks, pools, planter boxes and balconies. The test standard states that once an overburden is installed, even a small overburden like a drainage mat, it may cause the test to be compromised and inconclusive. The ASTM standard provides guidelines for equipment calibration and requires the detection sensitivity of the testing equipment is factory certified once per year to assure maximum confidence in the results of the test.

The most significant change presented in the latest ASTM standard comes from section 5.3 which states:

The substrate material directly below the membrane must be sufficiently conductive (approximately 10 4 ohms-per-square or less as determined using Test Method D4496) for the test method described in this practice to detect membrane breaches reliably. In most instances, a concrete substrate is sufficiently conductive to successfully detect membrane breaches using this method. In membrane assemblies, where the substrate is nonconductive, a conductive material can be placed directly under the membrane to facilitate testing.

The way I interpret this statement is, a conductive primer or a conductive material directly under the membrane is the only way to achieve a conclusive test and find the breach in the membrane. This creates an issue for the roofing and design industry. Unless the designer of record specifies a conductive primer or conductive material (wire mesh) directly under the membrane any ELD test of the membrane may not be accurate or conclusive. If there is no conductive material directly below the membrane, water would have to enter the membrane through a breach and travel through all layers of the system until it reaches the conductive deck. The water then creates a short circuit through all the materials causing the ELD equipment to alert. For new construction, the designer of record can simply specify a conductive primer when writing a waterproofing specification. On existing buildings without a conductive material directly under the membrane, the breach will have to be significant and create a short circuit between the membrane and the conductive deck. This “short-circuit” is water inside the waterproofing system.

Low voltage ELD is good for testing wide open waterproofing membrane that is not obstructed by penetrations and wall flashings. It is possible to test horizontal surfaces using low voltage ELD, however, special training and special roller equipment is required.

High Voltage ELD

High Voltage ELD requires a dry surface. A wet surface will provide false readings and make pinpointing breaches in the membrane impossible. The high voltage ELD finds breaches by detecting moisture in or around the breach. Unlike the low voltage ELD, the high voltage ELD does not require a “trace wire” around the area being tested. The ELD technician simply finds a ground to the deck. This ground could be a roof drain, a soil stack, a lightning rod terminal, or anything that is grounded to the deck. After grounding the ELD unit, the technician simply pulls a wand with conductive brass brushes attached over the membrane surface. Once a breach with moisture is found, the ELD equipment will activate and produce an audible beep when the brushes pass over the breach. The sensitivity of the ELD equipment can be adjusted to penetrate thicker membranes. The high voltage ELD can even be calibrated to detect areas where a liquid membrane does not meet the minimum thickness requirements of the specifications even if no breach is present.

High Voltage ELD has a high probability of false positive alerts if the equipment is not calibrated properly or there is moisture in the membrane. High voltage ELD cannot be used on conductive membranes like EPDM. If the waterproofing system has a conductive medium directly under the membrane, high voltage ELD will work in a similar fashion as the low voltage ELD.

Conclusions

Since ASTM published ASTM D8231-19 the industry now has guidelines for Electronic Leak Detection (ELD). The testing standard directs the ELD user to low voltage systems with conductive medium directly under the membrane. Does that mean that you cannot complete ELD on membranes without a conductive medium directly below the membrane? Absolutely not. The new ASTM standard does state for a test to be conclusive, a conductive medium must be placed directly under the membrane and the testing equipment shall be properly calibrated by the equipment manufacturer. Building owners and designers can still require ELD test on all projects, however, they must accept the fact that those tests may not be reliable.

Pete Keener, RRC, RRO, CIT

Department Manager - Building Science Solutions IntertekMr. Keener started his roofing career as a technical consultant in 1988. He was designated "Rooky of the Year" with The Garland Company. He developed extensive knowledge in SBS, APP and BUR roofing and trained to perform core sample analysis, field testing and quality control. His expansive work background includes project management, facility directorship, owning and managing his own roof consulting company, roof and building envelope consulting, assessments, inspection, maintenance program development and management and sales of roofing products. Pete has managed projects for schools, colleges, federal government national retail chains and more. Pete joined Intertek in 2020 and is a Department Manager and Senior Consultant for their Building Science Solutions Department. He is a Registered Roof Consultant (RRC), Registered Roof Observer (RRO) and Certified Infrared Thermographer - Level 1 (CIT). Pete can be reached at kerry.keener@intertek.com.