MAREK was pleased to contribute to this recent article on qualities to look for in a ceiling manufacturer. Check it out:

The following article was authored by Tom Murray and originally published in AWCI's Construction Dimensions magazine.

A top-notch ceiling manufacturer is distinguished by the ease their products offer customers, the relationships they build with contractors and the technical support they provide.

We all know time is money. This is especially true for ceiling contractors, whose work is usually wedged between electrical, HVAC, plumbing installations and later fit-out phases. Efficiency, then, is of the utmost importance, both for a project’s schedule and its budget.

Roughly 70% of ceiling installation cost is attributable to labor. So the experience of those installing the ceilings, the tools they use and the product itself is crucial. Ceiling manufacturers are taking this all into consideration when evaluating their business and their relationships with contractors.

Creating durable, dependable and easily obtainable products is the core of any manufacturer’s business, of course. But the demand grows for manufacturers to offer more than products alone. There has to be quality control—manufacturers must stand behind their wares. There have to be knowledgeable employees to foster client relationships. And there must be expert support for unforeseen on-the-job challenges.

Knowing what to look for in a ceiling manufacturer is good for your workflow—and your bottom line. Here are three rules of thumb to remember when considering ceiling manufacturers.

Innovations Drive Products

Innovations Drive Products

Manufacturers who think beyond the product are the ones striking a chord with contractors.

For example: a suspension system utilizing more frequent and higher hanger wire holes, which are spaced every 3 inches. This simple-but-effective innovation provides more hanger wire options higher in the tee, giving installers the option to use a closer hole and still get a strong hold in the suspension system, rather than going lower on the main tee and having to stretch farther or angle the wire. This also prevents interference with the wire when installing panels and eliminates the need to manually punch holes in tees for wire hangers that may be impeded by infrastructure within the ceiling or required in seismic applications.

Acousti Engineering Company of Florida is a commercial interior construction and acoustics company specializing in schools, universities and healthcare facilities throughout the Southeast. Associate Manager Darren Warwick appreciates how product innovation and support can reduce labor costs. “Manufacturers with knowledgeable reps who understand the products and also how they’re installed in the field are especially important to us as products evolve,” says Warwick. “Workers fighting with installation slows them down.”

To address needs like those of Warwick’s team, manufacturers need to focus on innovations that provide installation speed and versatility. For instance, a simple accessory clip designed by one manufacturer specifically for drywall ceilings can be added to main runners to accommodate up to 16 feet of unsupported spans. Innovations like these dramatically speed up the installation process, allowing workers to cover more area in less time.

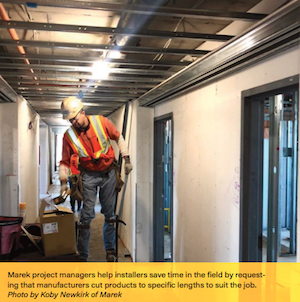

Koby Newkirk, field supervisor for MAREK, an AWCI member company in commercial construction services since 1938, used this ceiling suspension system to complete an entire hotel hallway ceiling in a single day with just one installer. However, Newkirk did have an additional trick to help shorten the installation time: product customization.

Customization is not commonly considered by manufacturers due to the challenges of getting precise measurements, accurate construction dimensions and meeting tight project timelines. But customization can be another tool in reducing labor costs. Newkirk saves time in the field by requesting that manufacturers cut products to specific lengths to suit the job.

“If you have repetitive dimensions of cross tees you can special order them, eliminating having to cut them at the job site,” says Newkirk. “It’s  important to factor in a longer lead time, but it’s a tremendous time-saver and helps reduce job site waste as well.”

important to factor in a longer lead time, but it’s a tremendous time-saver and helps reduce job site waste as well.”

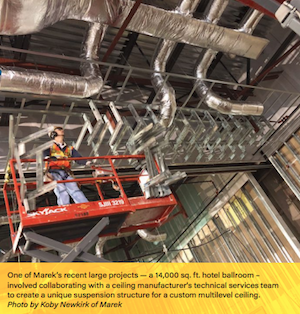

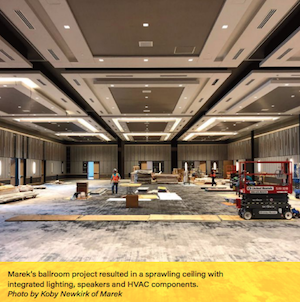

It’s important for manufacturers to collaborate with contractors to discover new ways to implement existing systems. One of Newkirk’s bigger projects—a 14,000 square-foot hotel ballroom—involved working with the ceiling manufacturer on a multilevel ceiling that was suspended without having to go all the way to the deck. While this was a technique he had implemented before, this was the first time he used it for such a large space. By using less material and fewer workers—the technique required only three installers instead of the usual 10 to 15—Newkirk saved tens of thousands of dollars. Plus, he was able to assign more crew members to other jobs, further extending his cost savings.

Contractors firmly believe that manufacturers’ innovative thinking leads to products that are easier for them to install. And saving time helps contractors offer lower bids on jobs. “High quality product that offers ease of installation significantly lowers our overall job cost,” says Rhone Schenker, president of Elevated Acoustics in Lakewood, Wash. What is saved on labor can then be passed along to the project owner.

In order to collaborate and innovate, it’s important for manufacturers to have specialists in the field, working with installers. Contractors want to work with companies that base their products on real-world applications.

A Good Manufacturer Is an Installation Partner

“We value manufacturers who spend time with our installers, making sure they understand the products while listening closely to their concerns,” says Schenker, whose team specializes in acoustical wood and metal ceilings. Recently, one manufacturer sponsored a ceiling grid installation class that Schenker taught at his facility. It showed him how much the manufacturer supported his company and, as a new firm—this is Elevated Acoustics’ first year in business—it was an important learning experience for his crew. Schenker believes in “training the team well so they feel confident at the job sites.”

Schenker’s biggest reminder to his installers is to make the ceiling grid square. He urges his project leaders to ask on-site specialists questions and, also, understand the architect’s intent before starting to build the grid. “Look for nuances and structural elements, such as window mullions, which architects frequently use as alignment guides,” he says. Even being off 1/16 of an inch at the start of the layout has big ramifications on the final grid installation. Careful thought and preparation in the beginning of the project avoids having to shift the ceiling later.

Manufacturers send field specialists to the job site—often within a couple of days—to help installers spot unique project details or to provide more immediate feedback, they may suggest sending reflected plans and project specifications directly to their office.

Support is especially important for sizable projects, agrees Warwick. It’s vital for Acousti Engineering Company of Florida installers to be efficient in the field, and having easy-to-reach support is critical to saving time and headaches on his jobs.

“The key is in pre-planning,” says Warwick. “When you first put your eyes on the job site, you can usually assess it fairly quickly and bring up any issues. It’s important to address concerns quickly, and deal with them as they come up. Manufacturers who are available to talk about materials and answer installation questions are very helpful.”

Manufacturers who provide help with important yet sometimes confusing details, such as ceiling codes, are especially valuable resources. This more technical support and knowledge strengthens trust and builds relationships. “I prefer to work with manufacturers who encourage a dialogue with the contractors using their products,” says Newkirk.

Don’t Be Afraid to Engage Manufacturers Directly

Experts encourage companies to do three things to ensure successful business relationships: listen rather than talk, be transparent and connect with customers.

Manufacturers who provide onsite visits to support installers and provide hands-on training are preferred by contractors. And better manufacturers offer training seminars and networking events at their headquarters to further build communications with the businesses using their products. Ceiling contractors firmly believe open communication is key to building a good rapport and feeling comfortable with a manufacturer. “We’re looking for manufacturers who are honest and willing to be supportive of our business, above and beyond standing behind their product,” says Schenker.

By innovating technically advanced and easy-to-install products, providing good technical support and welcoming questions and concerns, ceiling manufacturers can dramatically reduce contractors’ installation times. Becoming a valued partner and providing the right support eases contractor headaches, makes them more efficient in their work and, ultimately, saves them money.

Tom Murray is director of product management for panels and suspension systems for CertainTeed Architectural.