Unistrut’s new corrosion-resistant Unistrut Defender product line is specifically designed for products or tools in harsh and corrosive environments, providing a service life between Hot-Dip Galvanized and stainless-steel systems.

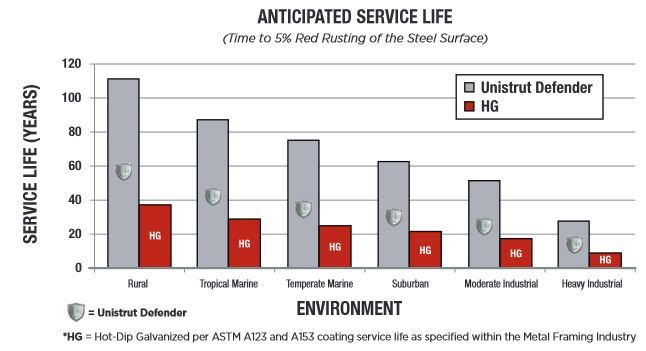

Independent testing shows that the new Unistrut Defender is three times more corrosion-resistant than Hot-Dip Galvanized products and avoids the use of costly stainless-steel hardware.

To ensure the strength and validity of Unistrut Defender, it was tested against Hot-Dip Galvanized products by an independent, accredited, third-party lab for 3,000 hours of continuous salt spray exposure per ASTM B117. At the conclusion of the test, five of the sixUnistrut Defendersamples still had not reached the 5% red rust failure criteria.

Therefore, the anticipated service life for Unistrut Defender outperforms traditional carbon steel framing systems and creates more than three times the corrosion protection of Hot-Dip Galvanized products, according to the Unistrut website. Unistrut Defender will meet the design life of most new applications, eliminating the need to replace parts over time.

“One of the unique characteristics of Unistrut Defender is that it contains self-healing properties. If the product is cut or scratched in the field, the finish will propagate into those areas eliminating the need for secondary touch-ups,” according to the Unistrut website.

Specifics:

1.Structural performance, including Slip and Pull-Out Loads, meets all allowable loads as specified in the Unistrut General Engineering catalog for carbon steels (refer to the Unistrut General Engineering catalog).

2. To achieve full performance and cost benefits, Unistrut Defender must be used as a complete metal framing system. In addition, Unistrut Defender must not be in contact with stainless steel materials due to a dissimilar metals condition that creates galvanic corrosion.

3. Some red staining may be observed on Unistrut Defender parts over time in corrosive environments. Red staining is superficial oxidation of the zinc/iron ions at the surface, and not corrosion of the substrate steel.

Finishes:

Unistrut Defender is a combination of two proprietary material coatings conforming to ASTM standards A1046 and A1059.

Materials:

Channel, Fittings and Pipe Clamps meet the physical requirements of ASTM A1011 SS GR 33.

To buy or learn more about Unistrut Defender products, contact UTF Unistrut salesperson, Laurie Chin, at laurie@unitedtoolandfastener.com.