This year I traveled to Fort Lauderdale, Florida to observe the hands-on portion of the 2016 ABC National Craft Championships. This is the first in a series of posts in which I will share excerpts from conversations with some of the people I had the pleasure to talk with while there.

This year I traveled to Fort Lauderdale, Florida to observe the hands-on portion of the 2016 ABC National Craft Championships. This is the first in a series of posts in which I will share excerpts from conversations with some of the people I had the pleasure to talk with while there.

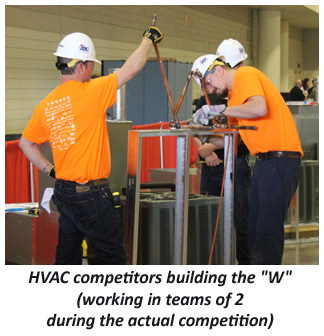

Mitch Clark works in project sales for Comfort Systems USA (Southwest), Inc in Phoenix, Arizona, but is also the current chairman of the ABC National Craft Championships. I spoke with him in the competition hall the day before the competitors would showcase their skills in the hands-on portion of the 2-day competition. While the competitors were sequestered in another area of the beautiful Greater Fort Lauderdale and Broward County Convention Center completing their intensive written exam, Clark spoke with me about the competition and about his role as a Project Manager for the HVAC competition. The HVAC competitors are required to complete a welding exercise. ABC has a partnership with the Washington Nationals baseball team, so for this competition, Clark created a mock-up of the Nationals logo – a “W” – which the competitors would be required to build in copper. The competitors would then pressurize the pipes and check for leaks as one part of the competition. They would also remove and add refrigerant from a heating and cooling unit such as might heat and cool a residence, and wire and power it up following a list of steps and checks. The third task of the HVAC contest involved making “elbows” out of sheet metal and putting them on the back of a commercial rooftop system to move the air in and out of the system. While the competitors perform these three tasks, judges will observe them and ask them questions about details of the work. The competitors would have about six hours to complete these tasks, and Clark predicted that it would take them that amount of time to do so.

The HVAC competitors are required to complete a welding exercise. ABC has a partnership with the Washington Nationals baseball team, so for this competition, Clark created a mock-up of the Nationals logo – a “W” – which the competitors would be required to build in copper. The competitors would then pressurize the pipes and check for leaks as one part of the competition. They would also remove and add refrigerant from a heating and cooling unit such as might heat and cool a residence, and wire and power it up following a list of steps and checks. The third task of the HVAC contest involved making “elbows” out of sheet metal and putting them on the back of a commercial rooftop system to move the air in and out of the system. While the competitors perform these three tasks, judges will observe them and ask them questions about details of the work. The competitors would have about six hours to complete these tasks, and Clark predicted that it would take them that amount of time to do so.

The event included 15 competitions representing 13 different crafts (electrical was divided between residential and commercial, and welding was also divided between structural and pipe). Each competition required competitors to complete specific, detailed tasks relevant to each of their crafts.  The competitors were brought into the competition hall late in the afternoon after completing the written exams so that they could be introduced to their work areas for the next day by the Project Managers for each of the 15 competitions. They were shown what they would be asked to do the next day and given a chance to ask questions.

The competitors were brought into the competition hall late in the afternoon after completing the written exams so that they could be introduced to their work areas for the next day by the Project Managers for each of the 15 competitions. They were shown what they would be asked to do the next day and given a chance to ask questions.

In addition to the craft competitions to take place the next day, there would be several demonstrations including safety, heavy equipment, and crane operation. The University of Auburn brought a drone to the event to spark the discussion of drone technology use in construction.

In the following 4-minute video, you can hear more of Clark’s comments, including how he and the Project Managers for the other competition areas try to ease the nervousness of the competitors with encouragement and humor, and his obvious joy serving as a committee member for the National Craft Championships over the past 17 years.

This was the 29th year for this annual event. The written exam counted for 25% of each competitor’s score, and the hands-on or practical part of the competitions counted for the other 75%.

Look for more video and photos from this amazing event in future posts on Construction Citizen.