PLAZA DURABILITY IMPACTS OF NEW ENERGY CODES

Every three years, the International Code Council (ICC) releases a new edition of their suite of codes and standards for constructing the built environment. Each issue seeks to increase the safety and energy efficiency of everything we as designers, contractors, and manufacturers build. However, these changes often create a need to adjust the way we build, even if our previous methods have been working well for decades. One area where there is evidence that detailing and installation methods need to be updated due to increasing energy code requirements is in the design and construction of plaza slab systems.

CODE CHANGES BETWEEN 2006 AND 2018

The International Energy Conservation Code (IECC) identifies the energy efficiency requirements for envelope design among other building systems.

It recommends three methods of evaluating building components for their energy efficiency, including the R-Value method. The code divides the United States into eight different zones, and then identifies the required R-Value that each system needs to meet. Designers are then tasked with layering materials to achieve the R-Value for their component and zone.

It recommends three methods of evaluating building components for their energy efficiency, including the R-Value method. The code divides the United States into eight different zones, and then identifies the required R-Value that each system needs to meet. Designers are then tasked with layering materials to achieve the R-Value for their component and zone.

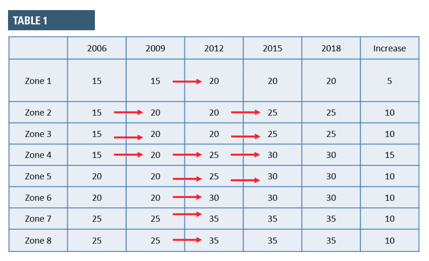

Table 1 illustrates the change in required R-Values since 2006 for the category ‘Insulation over Roof Deck,’ which is how plaza slabs are typically classified. On average, R-Values for the majority of the United States have increased 10 units, with Zone 4 rising 15. For this particular case, required R-Values have doubled in five code cycles.

PLAZA BASICS

PLAZA BASICS

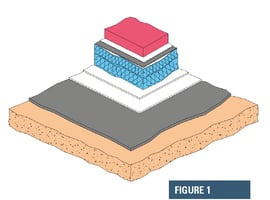

Plaza systems are typically used in the boundary between exterior supported space and an interior occupied space. Examples include between a parking garage and occupied space below, an on-grade plaza with below-grade space, or a rooftop patio and the building below. Plaza systems are sometimes referred to as sandwich slabs because of the layers of materials shown in Figure 1. The waterproofing (light grey), waterproofing accessories (white), and insulation (blue) are sandwiched between the structural slab below (dark grey) and the wear surface above (red). While the concrete and waterproofing options have not changed significantly since 2006, the increasing R-Values have resulted in increasing thickness of insulation. As the insulation has historically represented approximately 30% of the cost of a plaza system (excluding the structural slab), the ‘meat’ in this sandwich has gotten much more expensive.

PRIMER ON INSULATION

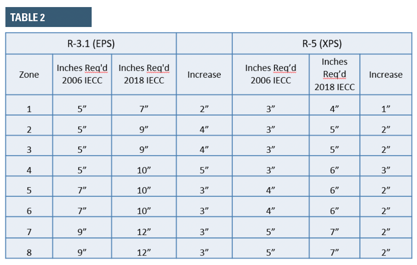

When we convert the 2018 R-Values into insulation thicknesses, as illustrated in Table 2, there are significant impacts on depth. Since the insulation is a large financial component of a plaza system and

it would take considerable effort to remove and replace the wear slab to fix any issues, it deserves to be given the same level of thought and detailing usually reserved for the waterproofing system.

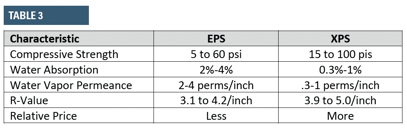

There are two types of insulation commonly used in plaza systems: EPS (white ‘bead board’) and XPS (blue or pink ‘foam board’). Table 3 compares the design characteristics important to consider when selecting which material is better suited for this type of installation.

The published characteristics of insulation each play an important role and should be considered in the long-term performance of the system. Having already covered the importance R-Value and relative price play, next to consider is compressive strength. The manufacturer publishes compressive strength values which are based on either 10% deformation or the yield strength. Taking a typical insulation depth of 6” per Table 2, 10% deformation would result in nearly 5/8” of deformation. This magnitude of elastic settlement in the insulation layers is significant, usually occurs in a differential manner as loading is often inconsistent, and therefore must be accounted for in design. Designers should select materials only after having considered the anticipated dead and live loads and wear slab tolerance for settlement. Often, after breaking down the point loads of items such as tires and planters, designers select a compressive strength which is higher than originally thought necessary.

The next characteristic to consider is the water absorption and water vapor permeance of insulation, which indicates how much water is likely to be trapped in the material and how water will move through the system. All plaza systems, by design, anticipate water passing through the wear slab and insulation layers on its way to drainage. In colder climates, this inevitably means the insulation layers will be wet and experience freeze-thaw cycles. Manufacturers unfortunately do not correlate the published values to a corresponding measure of freeze-thaw resistance. This is an important consideration, as our case studies have shown the ability to withstand these destructive forces varies greatly between the two types of insulation.

The next characteristic to consider is the water absorption and water vapor permeance of insulation, which indicates how much water is likely to be trapped in the material and how water will move through the system. All plaza systems, by design, anticipate water passing through the wear slab and insulation layers on its way to drainage. In colder climates, this inevitably means the insulation layers will be wet and experience freeze-thaw cycles. Manufacturers unfortunately do not correlate the published values to a corresponding measure of freeze-thaw resistance. This is an important consideration, as our case studies have shown the ability to withstand these destructive forces varies greatly between the two types of insulation.

CASE STUDIES

EPS Insulation

Test pits into existing plaza systems insulated with EPS ‘bead board’ insulation have shown favorable short-term (~two years) performance in colder climates, as seen in Photo 1. However, long-term (20+ years) exposure to freeze-thaw cycling has resulted in deterioration of the board into individual beads as seen in Photo 2. This breakdown of the insulation as a cohesive material causes the loss of its insulating and compressive strength characteristics. In most cases, this leads to cracking of the wear slab, damage to the waterproofing membrane, and even condensation on the underside of the structural slab below, prompting replacement of the entire plaza system.

XPS Insulation

Similar test pits were also conducted on plaza slabs insulated with XPS insulation. The short-term and long-term inspections of the insulation itself were both favorable, likely due to the physical characteristics of the board, as previously discussed and as illustrated in Photo 3. However, the success of the insulation board is sometimes accompanied by a failure in the wear slab. Because of the low absorption of the material, moisture remains on the insulation board, and freeze-thaw damage was observed on the bottom of the concrete wear slab, as shown in Photo 4. This creates a new need to ensure drainage paths are designed to handle water at multiple layers of the plaza system.

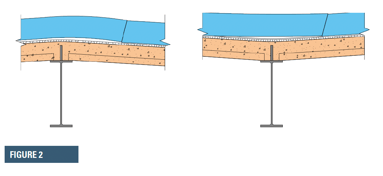

Also observed in wear slabs with rigid XPS insulation was a pattern of cracking that was thought to be due to insulation boards spanning over flexure points in the slab, as seen in Figure 2. The high and low points of a flexing system may create stress in the wear slab. To avoid this, installers must be diligent in installing joints at these areas to allow flexibility in the insulation.

DESIGN CHARACTERISTICS OF EPS AND XPS

In understanding the design characteristics of EPS and XPS insulation, and observing their performance over decades, there are some important lessons learned that designers and installers can carry forward into their next project. These include:

- For colder climates where freeze-thaw cycling is likely, XPS insulation is recommended over EPS.

- For vehicular or heavy-duty loading, XPS insulation is recommended over EPS.

- Regardless of which insulation is selected, choosing a compressive strength capable of supporting the type of loading anticipated is crucial.

- Wear slabs should be designed to withstand the anticipated deformation of the insulation.

- Drainage does not happen naturally through insulation boards. To prevent heaving and damage to the wear slab, design drainage from multiple layers.

- How insulation boards are installed matters. Install joints at the ‘hinge’ points in a slab to avoid cracking in the wear slab.

With the changes of the new codes for plaza decks and the complexity of design, it is imperative that lessons learned be followed for a successful and lived project.

This article was originally printed in SWR Institute's Spring 2020 Applicator publication.

Gregory J. Neiderer, PE, is the Director of Restoration and has 35 years in engineering and over 29 years with Walker Consultant’s Philadelphia office. Katheryn Stairs, PE, is Director of Operations with 20 years of engineering and 18 years with Walker Consultants at their Philadelphia office. For more information, Greg can be reached at 610.995.0260 or gneiderer@walkerconsultants.com and Kate can be reached at 610.995.0260 or kstairs@walkerconsultants.com.

Gregory J. Neiderer, PE, is the Director of Restoration and has 35 years in engineering and over 29 years with Walker Consultant’s Philadelphia office. Katheryn Stairs, PE, is Director of Operations with 20 years of engineering and 18 years with Walker Consultants at their Philadelphia office. For more information, Greg can be reached at 610.995.0260 or gneiderer@walkerconsultants.com and Kate can be reached at 610.995.0260 or kstairs@walkerconsultants.com.