On a sunny morning this spring, I stopped by the Brittmoore Field Office Trailer to visit with Roberto Sanchez, a project manager from Reytec Construction Resources, about a massive reconstruction project that they are working on. The project involves installing 5900 feet of new storm sewer, sanitary sewer, and water line underground along Brittmoore Road between Hammerly Road and Clay Road in Houston, Texas.

On a sunny morning this spring, I stopped by the Brittmoore Field Office Trailer to visit with Roberto Sanchez, a project manager from Reytec Construction Resources, about a massive reconstruction project that they are working on. The project involves installing 5900 feet of new storm sewer, sanitary sewer, and water line underground along Brittmoore Road between Hammerly Road and Clay Road in Houston, Texas.

The scale of the project is impressive. The diameter of the storm sewer alone begins at seven feet by four feet “boxes” and increases to eight by four feet openings.

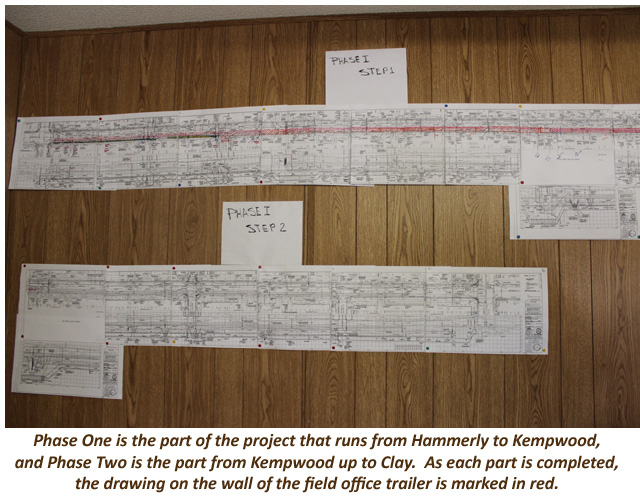

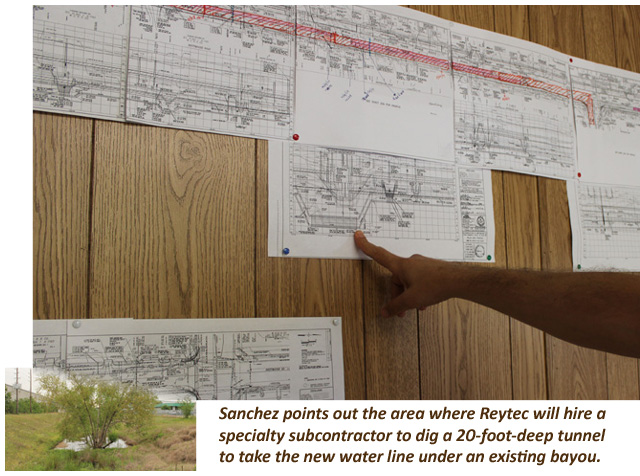

On detailed project drawings pinned to the wall of the field office trailer, I could see that Phase One is the part of the project that runs from Hammerly to Kempwood Drive, and Phase Two is the part from Kempwood up to Clay. As each part is completed, the drawing on the wall is marked in red. Sanchez pointed out the area where Reytec will hire a specialty subcontractor to dig a 20-foot-deep tunnel and install a casing which will take the new water line under an existing bayou. That part of the project must be done by hand with shovels so that the work can be immediately stopped if any ground instability or other hazard is encountered. I asked how long a project of this size takes to complete. Sanchez answered that their challenge is to complete this project in one year, even though the City of Houston has given Reytec 20 months to complete the work. Their goal is to complete the project safely and with the high quality that Reytec is known for in the shortest time possible.

I asked how long a project of this size takes to complete. Sanchez answered that their challenge is to complete this project in one year, even though the City of Houston has given Reytec 20 months to complete the work. Their goal is to complete the project safely and with the high quality that Reytec is known for in the shortest time possible.

Weather can be a huge factor in concrete work. “Rain is a problem, and you can imagine that in summer, sometimes we have to add ice to the concrete.” As concrete is mixed, it generates heat on its own, so on hot summer days the crew must add ice directly into the concrete mixer truck.

Sanchez’s work experience before he joined Reytec seven years ago included management – something he still enjoys. “I like to work with the guys in the field and to take care of scheduling the needed workforce, equipment, tools, and materials. I am like a supplier of all these.” He also works with the neighbors and businesses whose properties are adjacent to the project. The crews often work at night so that those businesses can have access from the street to their buildings during the day. Obtaining the concrete itself is one of the critical parts of Sanchez’s job. He must carefully plan each workday in advance, because the concrete is ordered from a supplier who delivers the concrete-filled truck on the specified day. The difficulty lies in the fact that these trucks must be ordered a week or more in advance, and other companies will also order concrete for their projects. Planning ahead is essential.

Obtaining the concrete itself is one of the critical parts of Sanchez’s job. He must carefully plan each workday in advance, because the concrete is ordered from a supplier who delivers the concrete-filled truck on the specified day. The difficulty lies in the fact that these trucks must be ordered a week or more in advance, and other companies will also order concrete for their projects. Planning ahead is essential.

The number of workers who are on this project averages around 30, but this varies depending on the tasks for each month. Paving, for example, requires extra workers because the job requires speed and timing. Underground tasks are performed by smaller crews of eight or nine, but require workers who have had extra training both in job skills and in safety.

Because safety is so important to Reytec, employees have a safety meeting every day first thing in the morning. In these meetings, they review Job Hazard Analysis worksheets so that the workers are reminded of the possible hazards that are associated with the tasks for that day, and the necessary safety precautions to avoid them.

At the end of my visit, Sanchez told me how much he enjoys working for Reytec. He said:

“Every day you learn something different. It’s a fun job, if you look at it that way, because every day is different. Good or bad, every day you have to face a new decision. We get drawings from the city, but we often find unexpected things once we start digging. And we cannot let that stop us – we have to continue with production. We have to meet with the foremen and superintendents to find a solution. It is not like a job where you sit down at a desk and the time moves very slowly.”

In addition to the photos below, I hope you will enjoy this brief video of what the work looked like that day:

Inside Look at Featured Craft: Underground Utility Concrete

by Elizabeth McPherson | June 25, 2014

Add new comment