Google 3D printing and you will get 281 million results in less than a second. As we have previously posted, most of the attention in the 3D printing world has been focused on the printing of houses in Dubai and China, the additive manufacturing for autos, medical implants, all prototypes for the future. The growth of 3D printing in the AEC industry, while still in its infancy, is finding its way into some interesting places.

Recently, AGC Houston chapter held its first Innovation Forum that featured the Gilbane Houston team of Ryan Shults, Dylan Sims and Josh Holmes. They presented one of the practical ways that their team used 3D modeling for a Houston project.

They really caught my attention because they are using the desktop 3D printer to build models of complex phased projects that can be used to sell a project in the interview and then used in the job shack for new employee and sub project orientation, safety zone definition, project phasing, laydown areas and project orientation for site tours for the owners and the users.

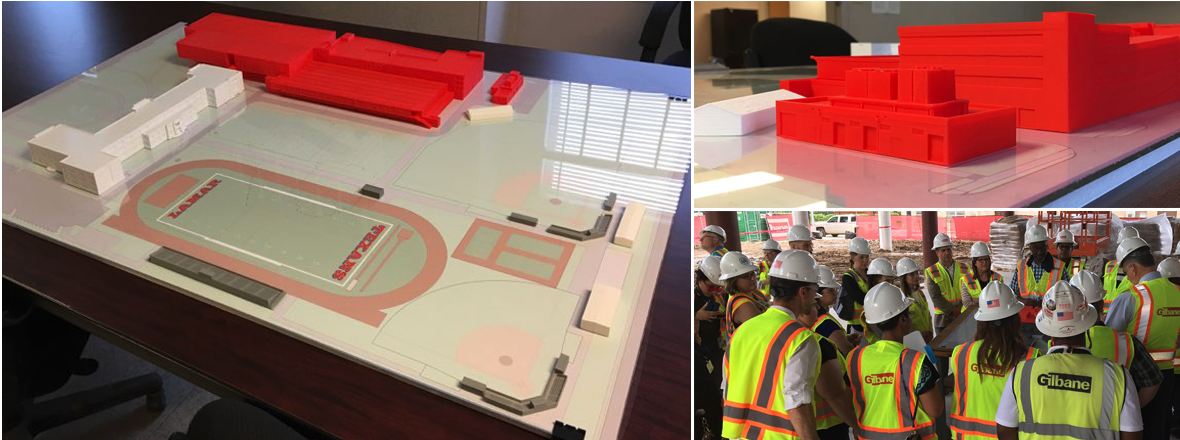

The project that the Gilbane team chose to illustrate the process is the renovation and expansion of the Lamar High School campus on a site on Westheimer, one of the busiest commercial streets in Houston. The project build is being phased to accommodate the school year and construction on the site. The build includes demolition, renovation and new construction. Gilbane is using two cranes which precipitates the need for safe lay down areas and access for the materials being delivered to the site. To illustrate the process for the build team, they created a 3D mass model on their printer.

Ryan and the team discussed the process they used to build the 1:20 mass model sized to the printing platform that they have, one of five across the Gilbane operations. Perkins and Will, the project architect, had sent Revit models to Gilbane for their use on the build. Those models included all the drawings and detail for a complete build, but it was too detailed for the team to use since they were only interested in the exterior of the building mass and the site layout.

In order to print the mass model of the building, something that architects and model builders normally spend days and weeks building by hand, the Gilbane 3D team translated the Revit models into Rhinoceros so that the interior detail was eliminated and only a mass model would be printed on the 3D printer. They then used a slicer to take the model to the printer. The printer that they used is the Raise3D N2 model that is manufactured by Raise3D, Inc.

The team color coded the demolition, renovation, not included and new construction when they printed the model. The tied the various colors to the Lamar School colors as a way to further tie the model to the site. What emerged from the process was a model that is well used in the build, at the job shack and in the office.

The audience asked, “What was the next use for this new technology.” The Gilbane team said that they would be taking the models to future interviews and would soon begin to 3D model sections through the buildings to illustrate the structure and the interior spaces. This technology will be complimentary in the move from the two-dimensional working drawings to the next generation of technology of virtual reality and augmented reality.

Other Gilbane offices are using the 3D technology to model scaffolding for hi-rise builds. The Gilbane team explained that the printing materials are becoming more sophisticated and exotic as in the use of titanium for medical implants.

We found that there are already existing businesses that will 3D print your building models for you on their printers so that you do not have to make the investment in larger scale models for your offices. We also learned that there are plans at NASA to use a 3D printer to build habitats on Mars using the existing materials found on the red planet.

The 3D printer technology is finding new horizons for the future, and Gilbane has found that there are very practical and innovative ways to use it in the AEC world today.