Hi there. The Chamberlin Man here. Let me tell you about a project that I am particularly proud of.

Chamberlin Roofing & Waterproofing is honored to have received an Associated Builders & Contractors (ABC) Oklahoma Excellence in Construction Eagle Award for their work on the Gaylord Family Oklahoma Memorial Stadium in Norman, Oklahoma. Judges selected the winning entries based on the following criteria: attractiveness of design, complexity, workmanship, innovation, unusual challenges or problems overcome, and more. Placing first at the local Oklahoma chapter qualifies Chamberlin to compete for a national ABC Excellence in Construction Eagle or Pyramid award.

Project Description

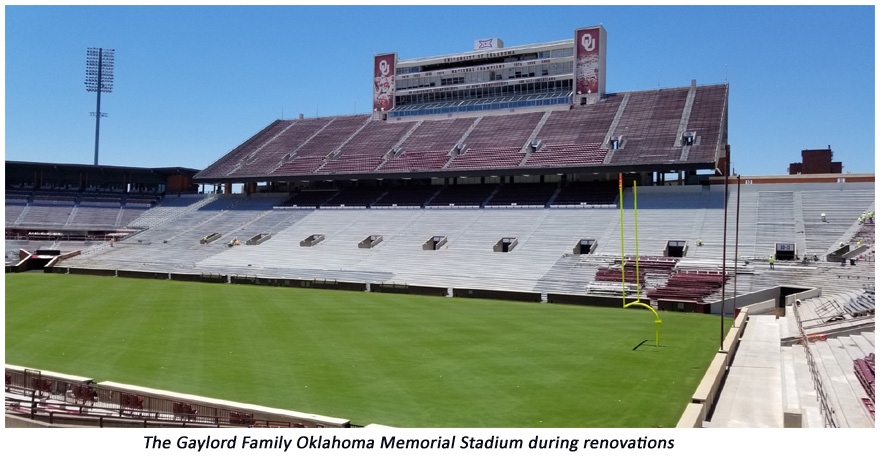

The Gaylord Family Oklahoma Memorial Stadium is one of the most well-known football stadiums in college football. With a total seating capacity of 82,112, the stadium ranks among the 15 largest on-campus facilities nationwide.

For years, the Gaylord Family Oklahoma Memorial Stadium has struggled with moisture intrusion specifically at expansion joint locations throughout the bowl. Multiple attempts to retrofit and repair these conditions have been made over the years. This evolved into an annual maintenance item for the university and created unnecessary repairs over the years.

Chamberlin was selected to find a permanent solution for the expansion joints and ultimately stop the leaks. Additionally, their scope for the stadium renovation included structural concrete repairs, crystalline waterproofing, epoxy injection, joint sealants, extending the concrete steps for widened aisles and adding intermediate steps to the east side of the stadium. Chamberlin used carbon fiber reinforcement (FRP) to repair and reinforce support beams under the stadium allowing them to withstand more force to increase the lifespan of the stadium. The west, east and north side of the stadium bowl had traffic coating removed and replaced and bentonite waterproofing was installed at the below grade walls where new concessions were built under the north endzone.

Quality Control

All of the manufacturers performed quality control inspections throughout the course of this project, and Chamberlin utilized their own quality control program to ensure adherence to industry standards for waterproofing applications. The traffic coating thickness was checked and recorded with a mil gauge every 200 square feet to ensure proper application. By conducting mil thickness checks, Chamberlin was able to prevent common downfalls of applying the material outside of the manufactures published literature. Common issues caused by inconsistencies in the membrane thickness are bubbling, blistering, elongation reduction, and could ultimately result in material failure.

When structural concrete repairs were completed, Chamberlin conducted a sounding test to ensure its structural integrity. By dragging a chain across the repaired concrete, the crew carefully listened for a distinct sound that would let them know if an area was hollow or not. Chamberlin successfully completed the repairs with no deficiencies noted. KFC Engineering conducted routine inspections of all structural concrete repairs including inspections of concrete patching and epoxy injection.

Scheduling

This was a very fast-paced project, as everything had to be completed within six months for OU’s first football game on September 1st. With the compressed schedule and weather days, Chamberlin had to execute multiple scopes simultaneously and plan accordingly.

Chamberlin knew they would be fighting poor weather conditions February through April during the rainy season in Oklahoma. Proactive planning was key to completing the project on time. Most of the waterproofing materials for this job could not be installed if it was actively raining or if there was a chance of rain, so the crew utilized that time to complete prep work for the structural concrete repairs, such as concrete demo and removal.

Once summer started, Chamberlin adjusted their start time from 7:00am to 4:00am. This not only protected the crew from heat-related illness but aided in the installation of the traffic coating. Installing traffic coating in high temperatures can cause outgassing which results in material bubbling that could ultimately lead to material failure. Moving the start time to 4:00am allowed the crew to take advantage of the cooler weather and support quality control while alleviating the stresses of high temperatures on employees. This aided in the production output of the Chamberlin crew as well.

Extenuating Circumstances

Along with the size of the project and fast-paced timeline, the OU Stadium was not shut down for the renovations. This meant Chamberlin had to work around OU activities such as the spring football game, commencement and other various events that were held in the stadium. Maintaining the field was a priority, and material storage space was extremely limited.

Phasing of the multiple trades’ scopes for an efficient workflow required much pre-planning and coordination. Prior to the start of the renovation, numerous discovery meetings were held to determine each trade’s needs. An added challenge was the removal and reinstallation of over 82,000 stadium seats around the traffic coating installation. Chamberlin’s Project Manager created a detailed schedule and phasing sequence for the project that determined who would work in what areas from day to day to maximize everyone’s time and avoid conflicts or slowdowns. This coordinating and scheduling was also utilized to prevent unnecessary damage to renovation finishes during the project.

Obstacles Overcome

One area in need of structural repairs was the blockouts and concrete inside the expansion joints in the stadium. To begin, Chamberlin cut out the expansion joints leaving them exposed while extensive repairs were completed inside the joint. If there was a chance of rain, all joints had to be closed in order to protect them from water infiltration. Chamberlin brainstormed an idea that would allow them to quickly protect the joints and efficiently resume repairs when the rain passed. The solution was a sheet membrane waterproofing which was easily installed to seal the joints and swiftly cut away to allow quick access to the work.

Chamberlin reinforced structural concrete beams underneath the stadium with carbon fiber reinforcement to stabilize the stadium and prevent settling that could cause future damage to the structural integrity of the stadium. Access to this area was challenging as the beams were below the stadium bowl but above a sub-roof. Approximately 25-foot high scaffolding was needed but had to be constructed without compromising the sub-roof or the safety of the personnel that would later work on the scaffold. Since the sub-roof did not have enough structural integrity to support the scaffold, the scaffold was built up to a tie beam to rest on for support. In addition, the traditional assembly of OBS frames would not fit in the area, so a modular scaffolding system with interlocking poles was erected.

Productivity

Lost time could be predicted due to weather delays and events that were being held in the stadium. With this is mind, Chamberlin increased manpower to help complete the project on time. Chamberlin brought in more technicians who had extensive knowledge in structural repair from other Chamberlin offices. Additionally, two extra superintendents were brought on to oversee specific scopes and aid in the timely completion of the project. The additional supervision, guidance for the crew and extra hands on deck elevated productivity and effectiveness of installation time.

Value Analysis/Engineering

In 2002, Chamberlin had completed the original traffic coating for the stadium. While the typical lifespan of urethane traffic coating is 5-10 years, this material withstood 17 years of pedestrian traffic in the bowl. Because of the superior life span, Chamberlin suggested the original product be substituted for what was specified for this renovation project. Similarly, Chamberlin noted an area for improvement in the expansion joints. Chamberlin’s recommended joint allowed a higher range of movement, gave them the option to choose a custom color that would match the traffic coating and were custom designed and prefabricated for every tread and riser condition. This eliminated the need for tricky field splicing of the material and ultimately helped reduce the risk of joint failure and leaks. The owner did not pay more but received a better-quality product that will be able to accommodate additional and unforeseen stresses for years to come.

Until next time, I'll be seeing you around. ![]()

![]()

![]()

![]()

![]()

Chamberlin Renovates the Gaylord Family Oklahoma Memorial Stadium

by The Chamberlin Man | November 15, 2019